SOLUTIONS

Design Support &

Engineering Services

The framework of Velosity’s success is supported by our industry-leading design support and engineering services.

We provide a fully integrated solution, addressing your challenges from end to end – from design for manufacturability through all aspects of the manufacturing process.

Early design involvement with the Velosity team is key to your successful product execution and cost-containment efforts.

WHAT WE OFFER

- DFM (Design for manufacturability) assistance

- Mold simulation

- Tooling design and manufacture

- Process development

- Validation / PPAP

- Program management

- Custom engineered solutions

DESIGN SUPPORT & ENGINEERING

Program

Management

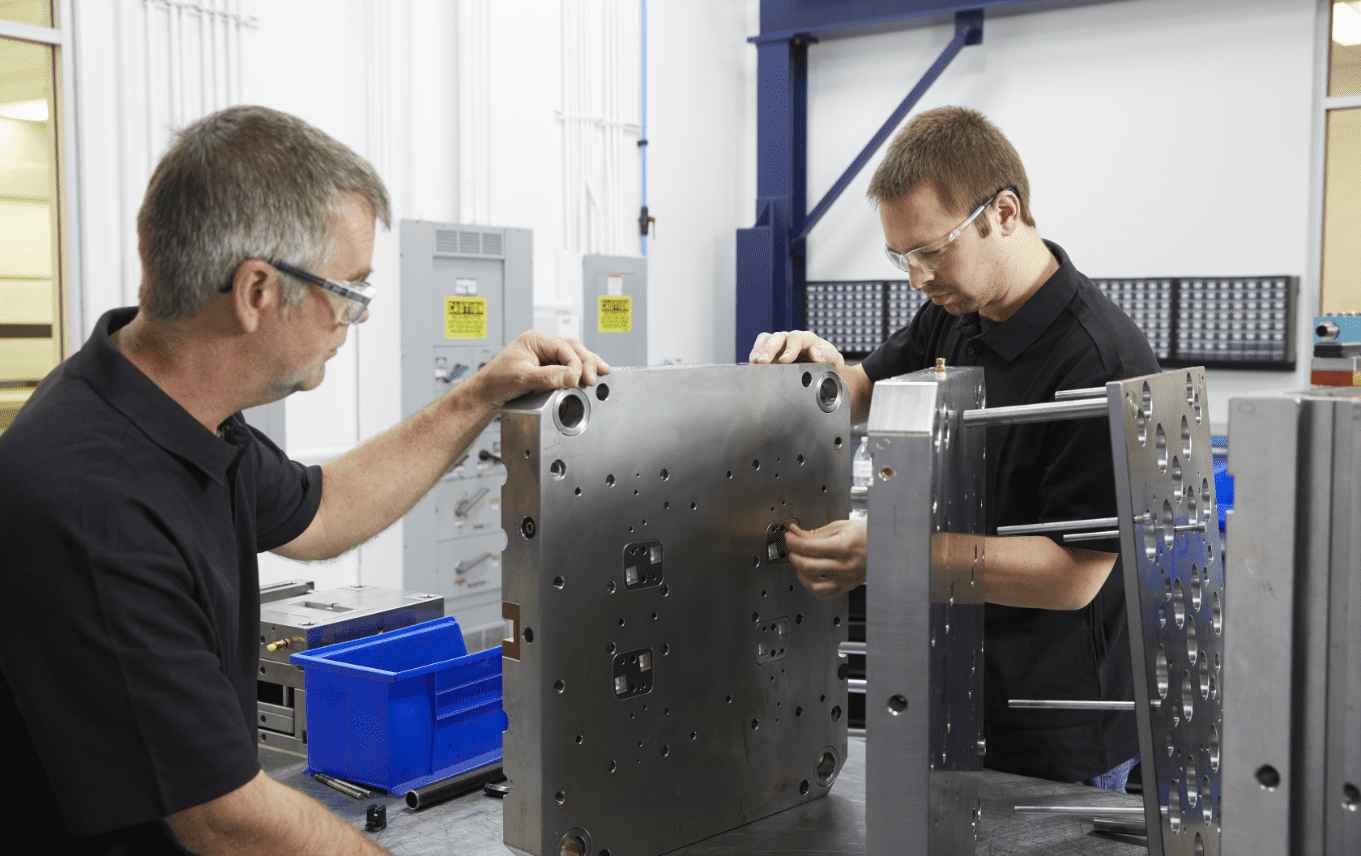

At Velosity, we approach each project as a team and become an extension of your organization. Collaboration is key to success and our experienced engineering professionals utilize their experience and your product needs to develop solutions to exceed your expectations.

DESIGN SUPPORT & ENGINEERING

Design for

Manufacturability

Our engineers and project teams are highly skilled at providing Design for Manufacturability (DFM) and Design for Assembly (DFA) support. We will recommend design enhancements, component consolidation and other considerations to reduce costs, optimize part performance and manufacturability allowing you to move expeditiously from design through qualification, validation/PPAP and into production.

DESIGN SUPPORT & ENGINEERING

Mold Simulation

Velosity is well versed in the use of Moldflow and similar molding simulation software. Predicting flow patterns and identifying potential mold filling concerns, such as sink or areas of high stress, early in the design phase will save time and costs later in the project.

DESIGN SUPPORT & ENGINEERING

Process

Development

Our process development team excels in the implementation of Scientific Injection Molding Principles. Process development starts with effective DFM, leading to superior tooling design, which sets the stage for robust process development and high quality products.

DESIGN SUPPORT & ENGINEERING

Validation

DESIGN SUPPORT & ENGINEERING

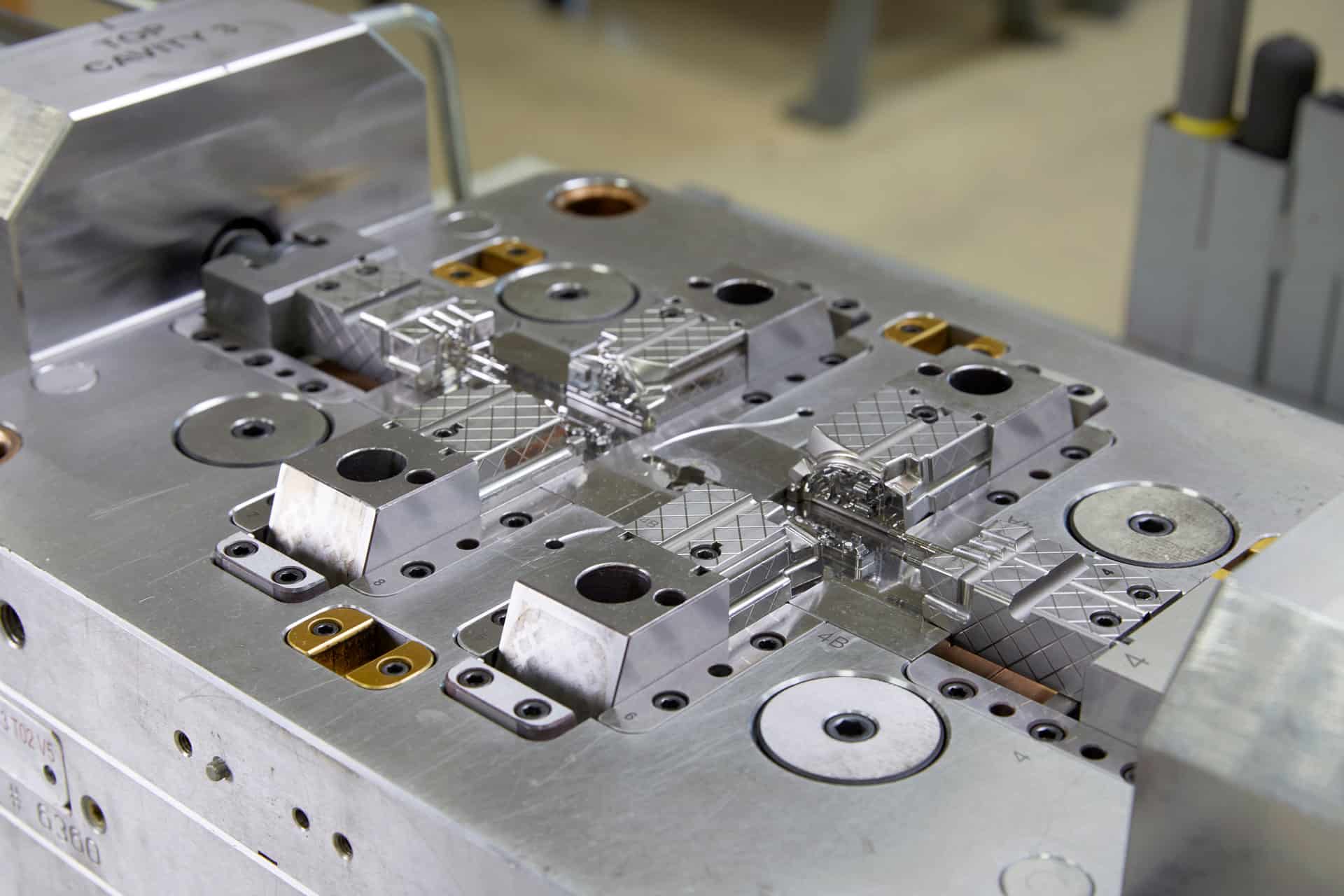

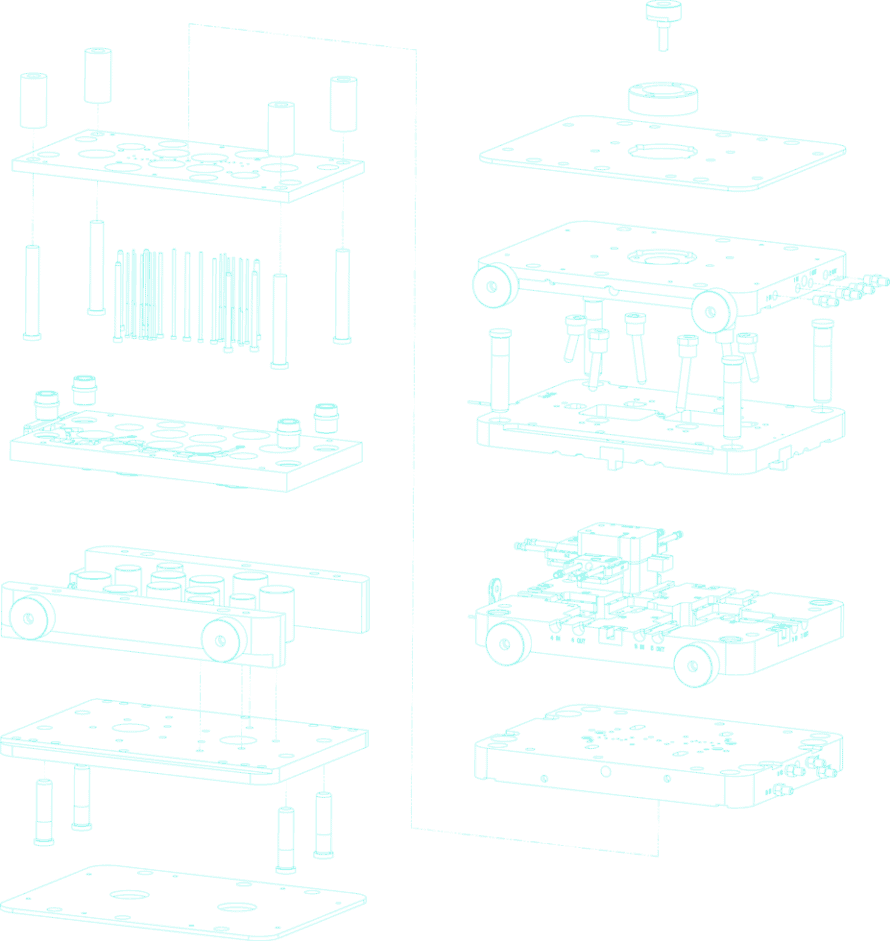

Tooling Design & Manufacture

Whether you want to fully participate in the mold design process or just receive parts, Velosity welcomes you as an integral part of the team. Our tooling support team outshines the competition in the areas of new tool development. Velosity is also able to integrate and refine tooling that is transferred from other molders.

Types of Tooling:

The type of tooling best used for your application is a function of a number of inputs. Part volumes, part complexity, part design confidence, material selection and product lifecycle must all be considered when selecting the type of mold to design and build.

• Lower volumes – consider master unit die (MUD)

• Similar part designs and materials – family tools may be a consideration

• Similar part designs and different materials – could warrant an interchangeable mold inserts

• High volume projects – multi-cavity and possibly a hot runner system

• High-cost raw materials – creative tool design solutions to reduce waste

Whatever your requirements we will help you select the best tooling options for your application.

DESIGN SUPPORT & ENGINEERING

Accelerated

Engineering Solutions

In order to support our customers dealing with engineering constraints, we have expanded our engineering services above and beyond providing our normal design for manufacturability (DFM) support.

Our accelerated engineering solutions include:

• Design for Manufacturability (DFM) support – Available on thermoplastic and silicone injection molded products and simple to moderately complex assemblies.

• Database Modification – Improve time to market by releasing tooling and products faster by utilizing Velosity’s database modification services.

• Material Selection – Take advantage of our experience with thermoplastic, elastomeric and silicone materials to recommend resin options for your application.